DUE TO MANY PRACTICAL PROPERTIES, OUR MODERN MATERIAL TRAPLAST™ MADE OF RECYCLED PLASTIC IS DETERMINED FOR THE USE IN THE MOST DEMANDING CONDITIONS WITH A MINIMUM NEED FOR MAINTENANCE CARE AND ALMOST UNLIMITED LIFETIME.

PRINCIPLES OF WORKING WITH TRAPLAST™ MATERIALS

TRAPLAST™ PLASTIC MATERIALS SHOW THE SAME VALUES AS ANOTHER MATERIALS AT HEAT CHANGES WITH THERMAL EXPANSION IN THE IN THE EXTENT OF 1.2-1.8X10-4 K-1, WHICH IS HIGHER THAN FOR WOOD OR METAL.

The value of the thermal expansion coefficient indicates the change of the length of the plastic profile long 1 m when the temperature changes by 1° c. for the sake of clarity, please see the following table:

| TEMPERATURE CHANGE | PROFILE IN LENGTH OF 1 M LIFE | PROFILE IN LENGTH OF 2 M |

| ∆20 °C | 3 mm | 6 mm |

| ∆40 °C | 6 mm | 12 mm |

The stated values signify that it is necessary to take into account a sufficient expansion allowance during the assembly. Its size is determined with regard to the method of use, the size of the expected temperature range which the product will be exposed to, the construction materials used, the method of joining the parts, the spacing of the connecting points, etc. When screwing, it is generally recommended to drill larger screw holes and avoid overtightening of screws. For other mounting methods, leave a sufficient expansion gap (Figures 1 and 2). Observing this principle is very important for a good result of a work. Traplast™ products are weather-stable and resistant to mould, fungi and chemicals. They can be machined with metal or wood tools. We recommend to use a saw blade for cutting the Traplast™ products. The plastic profiles are very strong, however they have a larger deflection compared to the classic wooden profiles. Products may also temporarily change over time due to the uneven heat stress. The temperature resistance of Traplast™ products is -30 to +70 ° C. Even concrete can be used to anchor all products into the ground. For better fixation of the plastic profile, we recommend to anchor its lower part using nails, screws or other in another way. Traplast™ products can be successfully surface-modified using coating colours Socrates or Luxol. More demanding applications and design solutions should be consulted directly with the manufacturer.

PLASTIC FENCES

Plastic fence laths, which are attached by zinc-plated self-tapping screws onto horizontal beams are determined for the construction fences from our elements. These are made of hot-dip zinc-plated square tube, which is also coated with plastic, thus greatly increases its life. In order to avoid fence bending or other deformation of the fence field, the lower horizontal beam must be attached to the posts so as to “work” downwards and upwards by about 10-15 mm. Using this way, the thermal expansion of the plastic material is completely eliminated because the beam can move up and down. Another method of mounting, when the two beams are firmly attached to the fence posts and the expansion hole must be pre-drilled into each fence is more laborious and time consuming and, due to the thermal expansion, it does not guarantee a resistance of the fence bars to deformation or avoidance of breakage of the screw fastening bolt fixing the fence to the beam. The use of our plastic profiles as horizontal beams for the construction of fences is only suitable for low and short fences, e.g. small fences for the optical distribution of the garden. In this case, however, the fence field must not be longer than 0.75 m, otherwise, due to the thermal expansion of the material, the deformation may occur.

INSTRUCTIONS FOR INSTALLING THE TRANSFORM FENCE SYSTEM

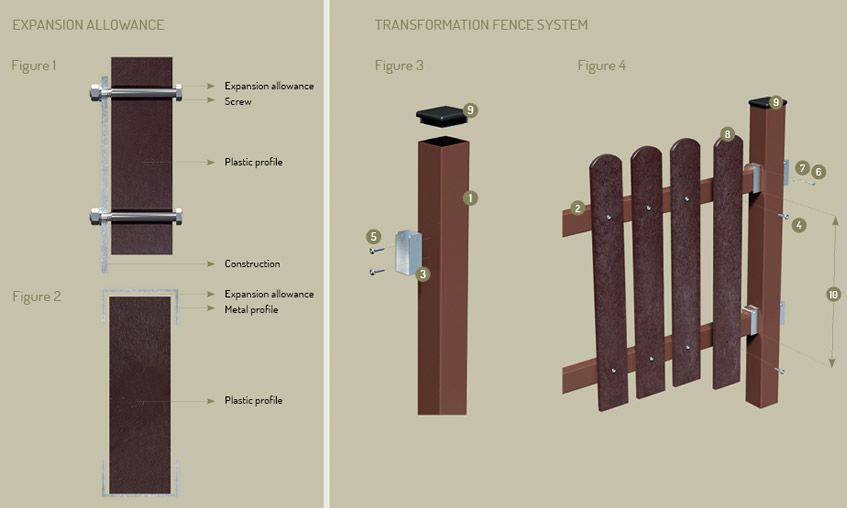

ELEMENTS OF THE TRANSFORM FENCE SYSTEM

- Posts 60 × 60 mm, material - zinc-plated iron square tube with coloured plastic finish

- Horizontal laths 50 × 30 mm, material - zinc-plated iron square tube with coloured plastic coating

- Square tube fasteners, material - coated zinc-plated sheet metal

- Set of self-tapping screws of 4, 2 x 38 mm for fixing the fences to the square tubes

- Set of self-tapping screws 6 × 15 mm for mounting the square tube fasteners to the posts

- Set of screws 4 × 40 mm with nut (7) to secure the fence field (square tubes) in the fasteners

TECHNIQUE OF MOUNTING THE FENCE SYSTEM

After installing the fence posts (1), mount square tubes (3). The fasteners are mounted with self-tapping screws (5). Before attaching square tube fasteners (3) using the self-tapping screws (5), it is necessary to drill holes with a diameter of 4 mm into the post (1). Assemble the tightening square tube fasteners to the posts with the holes up - so that the embedded square tube rests on the bottom and side parts of the fastener. The spacing and positioning of the square tube fasteners on the post (10) are determined by the length (height) of the fence planks (fences) (8) and determined by the customers according to their needs - see the Figure 4

Square tubes in the size of 50 × 30 mm (2) are inserted into the attached fasteners (3), which may, but not be necessarily, be fitted with end caps from both sides. Gradually, using the self-tapping screws (4), the fences (8) are mounted on square tubes. Before fixing the fences using the screws, holes with a diameter of 3 mm must be drilled into the fences and square tubes. The entire finished fence field is fixed to the square tube fasteners (3) by means of screws (6) and nuts (7) in the holes in the upper part of the fasteners. The gap (approx. 15 mm) formed between the fixing screw (6) and the square tube (2) is necessary to eliminate the thermal expansion of the fence planks (8). At the end, the posts (1) are fitted with end caps 9). .

ENTRANCE WICKET DOORS AND ENTRY GATES

The supporting structure of gates and wicking doors is basically made of the classical materials, preferably the metal profiles, to which the plastic fences are attached by means of gate screws (see the Figure 1). Prior to this, however, it is necessary to pre-drill a metal hole of at least 2 mm larger than the screw diameter to fix the fences (depending on their length). This expansion hole cannot be pre-drilled in the fence, since the conventional door screws have a fixing face under the head which, when assembled, is pressed into the fence and the effect of the dilatation opening is thereby eliminated. For flexibility of the joint, it is necessary to put a pad under the nut. Do not overtighten the nut, tighten them so that the fence in joint can react to temperature changes. We recommend you to consult the manufacturer a use of other structures if desired.

PLASTIC GRASSING PAVEMENT

The construction of paved grass areas has to comply with the CSN 736131-3, including the treatment of the sub-soil, the lower base and bed layers and the building materials used. According to this standard, all construction works and the transport and organizational measures and car park renewals must be carried out. The vegetation panels must be laid so that a gap of at least 10 mm is maintained between the parts, and the side of the panel with smaller holes is facing the loading layer. The grass pavement LITE is designed for passenger and commercial vehicles weighing up to 3.5 tons. Based on our experience and the experience of our customers, a well-compacted original sub-soil with approx. 10 cm of well compacted sifted soil with sand with a grain diameter of 0-4 mm is sufficient for the carriage of passenger cars around family houses, cottages, garages and gardens sufficient. Grass paving with a thickness of 6 cm is determined for the consolidation of areas for trucks, buses and tractors heavier than 3, 5 tons. According to the CSN 736131-3, the sub-soil should be two-layered. We recommend a gravel of 100 mm height for the lower layer with a grain size of 0-32 mm. After its compaction, prepare a 50-100 mm thick top layer consisting of sand or fine grain of 0-4 mm. Blocks deposited on thus prepared sub-soil are covered with suitable ground with the grass seed. As a general rule, in all cases, the mesh paving should only be covered up to 3/4 of their height so that grass does not exceed the level of the grassing pavement after taking roots. The full use of grassing pavement depends on its quality grassing.

PLASTIC TERRACES

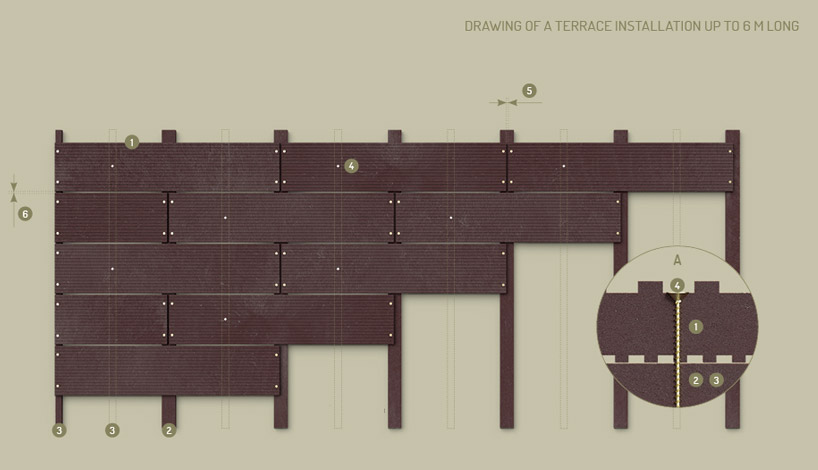

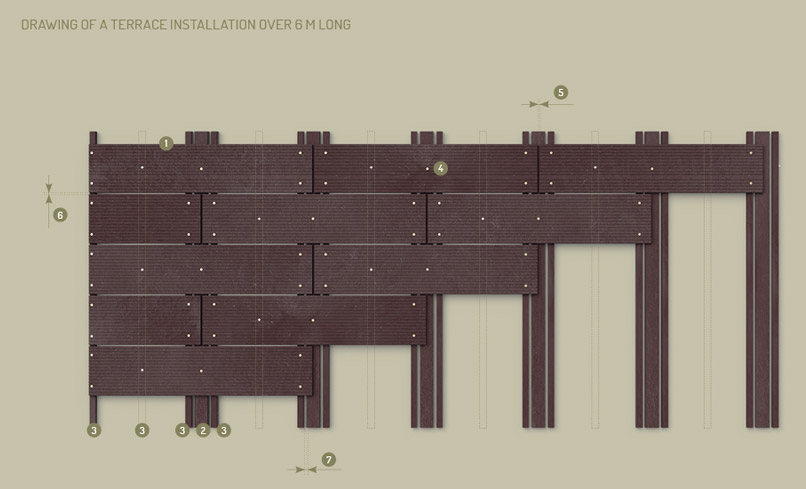

ELEMENTS FOR ASSEMBLING TRAPLAST™ TERRACE

- Grooved decking boards - terraced

- Joist 80 × 40 mm

- Joist 40 × 40 mm

- Self-tapping screw with recessed head 5 × 60 mm

BEST PRACTICE FOR MOUNTING TERRACE

The installation of terrace plates from Traplast™ is carried out at temperatures of about 20° C. At considerably different temperatures, we take into account the thermal expansion of the boards (1) and suit the dilation gaps 5, 6 and 7. We recommend using the surface-mounted screws with recessed head 5 × 60 mm (4) for mounting the boards. Always place the screw in the board groove so that the top of its head is exactly at the bottom level of the groove when screwed, see the detail A. The holes for the decking board screws must be pre-drilled at least two mm larger than the screw diameter. Always mount the patio boards on the base structure consisting of base profiles (2) and (3), see the drawings and description of the mounting procedure below, and adhere dilatation gaps between the longitudinal and transverse sides of the boards. Size of dilation between the shorter sides of the terrace boards (5) should be 7 mm and between the longer ones (6) 3 mm. Also pay attention to the approximate distance between each base profile - see both mounting drawings. If the terrace is adjacent to the wall, then a gap of at least 15 mm must be left between the wall and the basement structure. Unless the terrace is enclosed by a wall, it must be enclosed by a suitable trimming element, such as a garden curb made of Traplast™ material. This avoids undesirable movement of the terrace. Decide the mounting procedure depending on the longitudinal length of the terrace – up to six meters of the longitudinal length or over six meters the longitudinal length – see the mounting drawings. Due to the method of bedding of the base joists (2) and (3) and the fixing of the boards (1) for the terraces long over six meters, the thermal expansion is spread over in individual 1,5 m segments and thus there is no threat of an excessive change in the length of the terrace as the whole. For the proper functioning of this system, it is necessary to fix the joists 80x40 mm (2) to the base of the terrace to avoid any undesirable shift. When assembling base joists (3) (2) (3) keep a gap of 20 mm 7 between them.

STORAGE

Products made of Traplast™ are stored on shipping pallets, which must be placed on the reinforced straight floor. Storage is possible up to a maximum of two layers. If a shipping pallet is unavailable, the products are stored so that they lie on a reinforced floor in their entire length. In the opposite case, especially during lengthy storage, there is a risk of distortion.

COLOURS AND COLOUR FASTNESS

Coloured products are mass-dyed, nevertheless, they may contain spots of different colours up to a size of 1 cm2. Individual supplies (production batches) may vary from each other. The grey colour is undyed, so there is no option for colour shade. Due to the raw material used, it is not possible to guarantee the same colour shade of light colours (brick red and grey) for individual production batches. Weather elements can result in changes of original colour of Traplast™ materials to lighter shades, so called patina. These colour changes cannot be acknowledged as claims of defect.

DIMENSIONS AND WEIGHT

Product dimensions are measured at a temperature of 20 °C and are valid within the following tolerance:

| Up to 100 mm | ±3 mm |

| 100-1000 mm | ±10 mm |

| Over 1000 mm | ±20 mm |

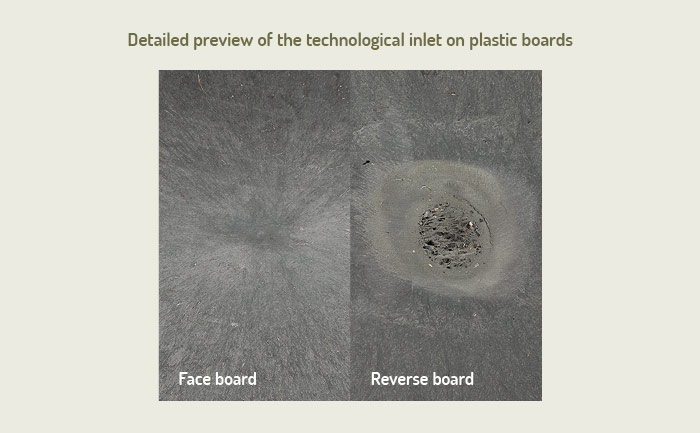

DETAIL OF THE TECHNOLOGY INTAKE ON PLAIN BOARDS